Wet Electro- static Precipitator (WESP)

By introduced American WESP and combined with customer’s requirements, we R&D a wet electro- static precipitator.

Application status:

Foreign application status:

It is firstly applied on the manufacture of sulfuric acid and metallurgical industry in 1970. Then, In 1986, it is applied on the coal-fired power plant. According to incomplete statistics, there are more than 50 sets have been used in American, European and Japanese power plant and various of successful experiences have been gained. Such as, WESP reconstruction of 315MW WFGD system for NB power company Dalhousie power plant in 2000; 2x750MW unit for Xcel energy company Sherbume power plant in 2001 and 3x350 MW unit for NB power company Coleson Cove power plant in 2002.

Domestic application status:

It is a very matured technology that have been applied on metallurgical and sulfuric acid industry. A standard of flue gas WESP (JB/T6409-2008)has been set. The application of WESP in large coal-fired power plant is still in the starting phase.

Features of WESP

Dust emission amount can be low to 5mg/Nm3

Removal efficiency of PM2.5 can be more than 90%

Nowadays, it is the most efficient solution to pollutant treatment

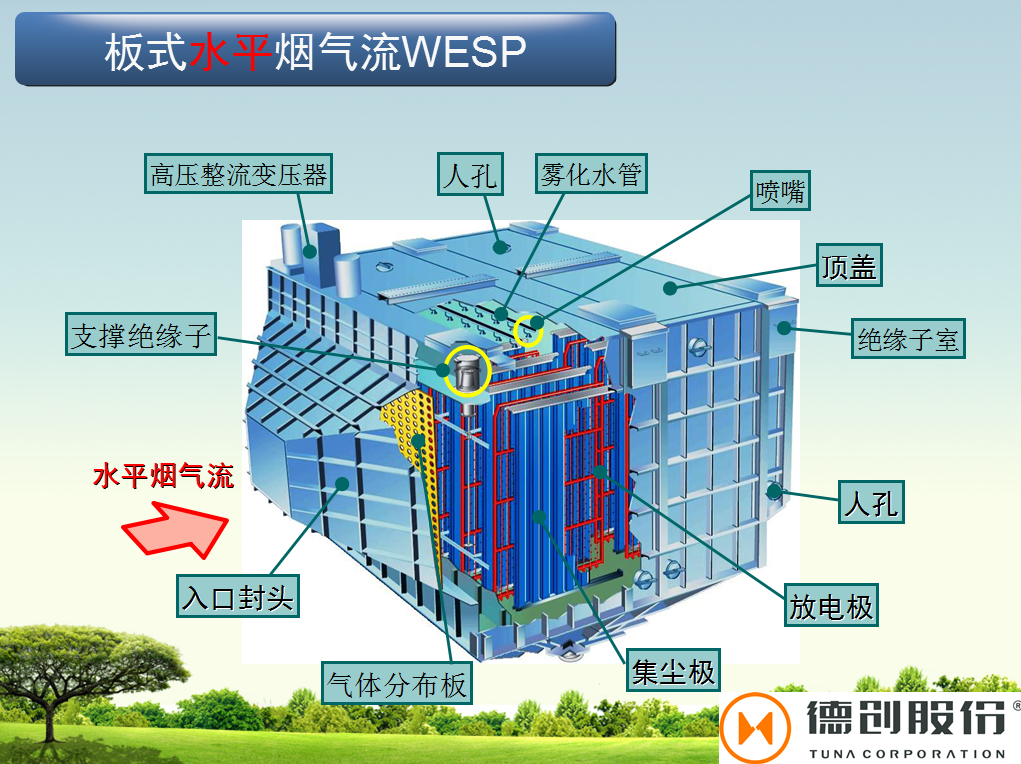

Working priciple

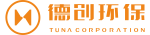

Major component:

Shell, inlet smoke box, discharge electrode, collecting electrode, washing system, circulating water system, high voltage power supply, outlet smoke box, air flow distribution plate, electronic control system and son on

Technical features and advantages of WESP

Dust collecting performance does not pertain to the characteristic of dust. It is much easier to collect the dust if it has higher viscosity, however, it is also applied to deal with the flue gas with high humidity.

Avoiding the phenomenon of back corona and preventing from reentrainment of dust

No dust accumulation on polar plate

Equipment layout can be more compacted by raising the speed of electric airflow velocity and minimizing the slant angle of ash bucket in electric precipitator

No moving parts makes it much more reliable

It can reach to the ultra low discharge standard of below 10mg