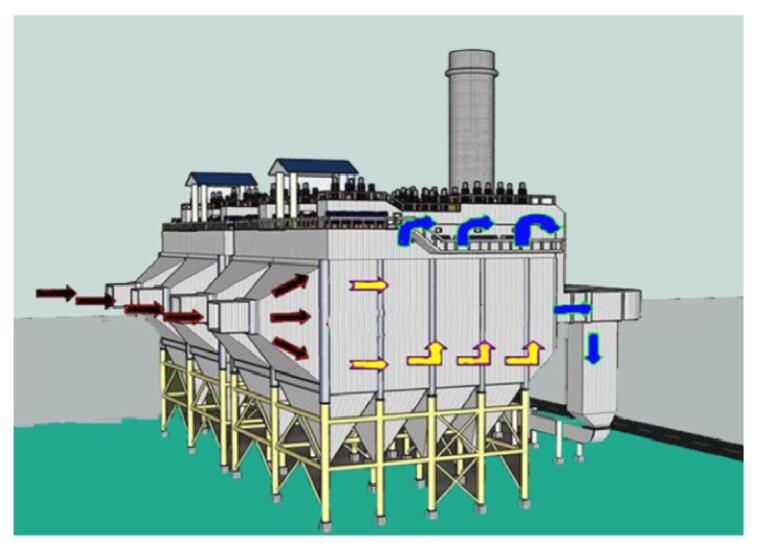

Electric-bag composite dust collector

Working principle

This technology combined both electrostatic precipitation and dedusting filter by reasonably placing the electric field and filter bag area inside the box. Generally, electrostatic dedusting area is placed before the filter bag area and these two will be tandem arranged. By cathode discharging and anode collecting, most of the dust can be collected. The efficiency can reach to 85%. Meanwhile, ionized those uncollected ashes. The after filter bag dedusting area collect the rest of flue gas with low dust content. The emission concentration can meet the environmental requirement (less than 20mg/Nm3).

Major component:

Inlet smoke box, anode plate, flow equalizing plate, sack, ash bucket, air chamber, stam pocket, pulse valve, outlet smoke box, electrical control system and so on.

Features of technology

With mutually combined both electrostatic precipitation and dedusting filter, the high efficiency, low-resistance and low energy have been highlighted. Moreover, the advantage of insensitivity to the type of coal is also been developed. The ratio of collection can reach to 99.98% and ensure the emission standard of 30mg/Nm3.

The character of dust can not have influence on the efficiency of dedusting and this can meet various kind of working conditions.

The small dust load, low running resistance (<1200Pa), long service life of filter bag(>4 years), small consumption and less maintenance cost and investment.

By using the newest efficient filter bag, the dedusting efficiency of superfine particle PM10 and ultrafine dust PM2.5 is very high.

Design Principle

controlled the flow field

Reasonable design parameter

The electric dust collectors are designed in polarity assignment

Top-quality filer bag

Reasonable bag cages and reliable pulse valve

High-efficient dedust system

Comprehensive monitoring

Patents